MAGNECTIC PARTICLE INSPECTION

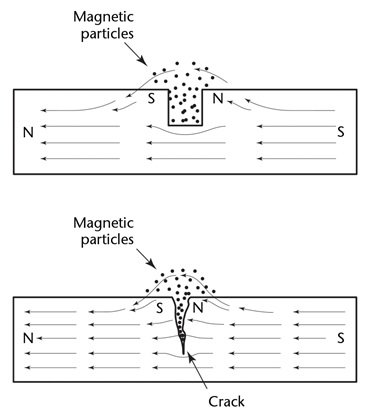

Magnetic particle inspection (MPI) is a method we use for non-destructive examinations. This is especially useful when dealing with components that are primarily comprised of ferromagnetic material like iron or steel. A part is examined by first being magnetized to create a small field within the part where its flux is uninterrupted. A crack or defect can be see when this flow is broken. Through the use of iron particles in a liquid solution, flaws can be seen under ultraviolet light when the particles bundle together in the leak in the flux.